Description

Body Material: Nylon

Colour: Black Nylon

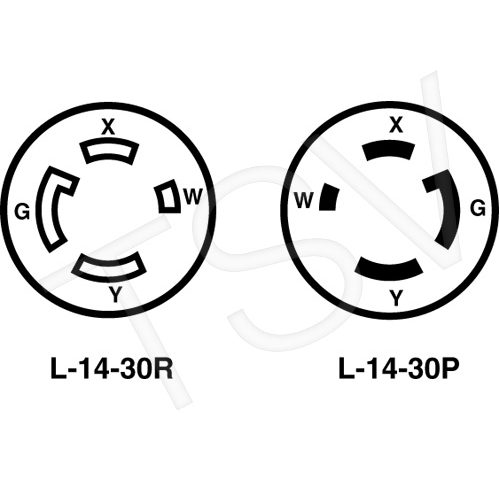

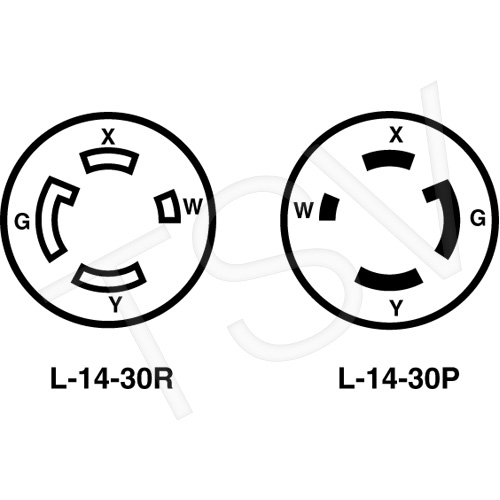

Angle: A plug or connector that allows the attached flexible cord to exit at right angles.; Corrosion resistant: A plug or connector constructed of special materials and/or suitably plated metal parts that is designed to withstand corrosive environments. Corrosion resistant devices must pass the ASTM B117-13 five-hundred hour Salt Spray (Fog) Test with no visible corrosion.; Dust Proof: A plug or connector designed so that the dust will not interfere with its operation. The IP Suitability Rating designates the degree of protection a device offers against the ingress of foreign objects. (e.g. IP20).; Explosion Proof: A plug or connector constructed to meet the requirements of hazardous locations as defined by the National Electrical Code, NFPA-70.; Hospital Grade: A plug or connector designed to meet the performance requirements of high-abuse areas typically found in health care facilities. These plugs are tested to the Hospital Grade requirements of Underwriter’s Laboratories Inc. Standard 498.; Locking: A plug designed to lock into a matching connector or receptacle configuration when the plug is rotated in a clockwise direction. The plug can only be removed by turning in a counter-clockwise direction.; Midget: A plug or connector designed with a smaller body diameter than standard plugs with a similar rating.; Moulded-on: A plug or connector that is factory moulded to a length of flexible cord.; Pin & Sleeve connector: A connector with hollow, cylindrical sleeve-type contacts.; Straight Blade: A non-locking plug that is inserted at a right angle to the plane of the matching device face.; Weatherproof: A plug or connector specially constructed so that exposure to weather will not interfere with its operation.